Nebulization of liquids with very low mass flowsup to 20 mg/h and very high mass flows up to 300 g/h

Droplet aerosols are needed for many applications in research,development and quality assurance In particular for quality development and quality assurance. In particular for quality assurance and calibration of particle measurement devices,Palas® aerosol generators ensure clear results due to their reliable characterisation.In order to be able to perform practical analyses and comparisons, droplet aerosols must be generated from fluids that are also used in the real world. Fluids such as H2O, DEHS,motor oils, white oil etc. differ significantly in viscosity, surface tension and density. Depending on the fluid, different atomisation principles offer particular advantages.In the PLG system, a nozzle system developed by Palas® is used.

Depending on the application, a special nozzle with heating option is used to adjust the desired particle size distribution and concentration quickly and reproducibly.

Advantages:

• Excellent short‐term and long‐term dosing constancy

• Heatable

• Best repeatability with respect to particle size distribution and particle concentration

• Large mass volume range (very low and very high)

• Long dosing time over several days with automatic refilling (optional)

• Robust design

• Robust design (optionally resistant against chemically aggressive fluids)

• Compact and light

• User‐friendly operation, proven in industrial applications

• Reliable function

• Low maintenance

• Reduces your operating expenses Example applications:

• Filter industry/oil separators

• Determination of separation efficiency

• Determination of fractional separation efficiency

• Load test

• Test of cooling lubricant separators

• Comparison of particle measurement devices

• Tracer particles

• Flow visualisation

Acceptance procedure measurements:

Thanks to their particular characteristics, the aerosol generators of the AGF system by Palas® are exceptionally well suited for of the AGF system by Palas® are exceptionally well‐suited for acceptance procedure measurements for clean rooms,testing of HEPA/ULPA filters and for leak tests and have been successfully employed worldwide.

Technical parameters:

• Particle material: according to customer specifications,motor oils, DEHS, paraffin oils

• Particle sizes: according to customer specifications,50 10 50 nm–10 µm

• Mass flows: according to customer specifications,20 mg/h–300 g/h

• Volume flows: approx. 2–110 l/min

• Power supply: 115/230 V; 50/60 Hz

Accessories:

• Transportation case for PLG 2000 and 2000 H

• Compressed‐air adapter

Series PLG Quality in detail

Function

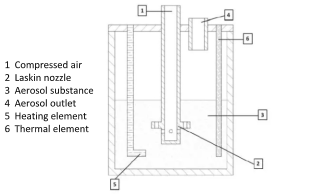

The liquid to be dispersed is simply filled into the reservoir.® The nozzle system developed by Palas® is immersed in the fluid.

Depending on the type of device, the nozzle system can be exchanged by the customer for lower or higher mass flows.

Fig. 1: Schematic representation of the aerosol generator PLG2000 H This nozzle system is based on the Laskin principle and guarantees extremely precise dosing constancy with uniform particle size (see Fig. 2).

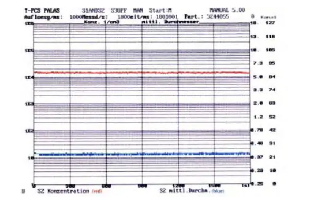

Fig. 2: High constancy of the particle concentration and the average diameter over time for a resolution of 6 saverage diameter over time, for a resolution of 6 s.

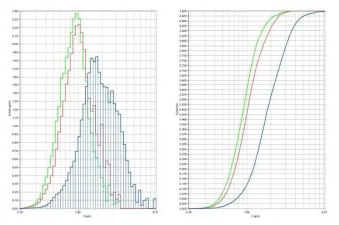

In order to test the function of the oil aerosol separators atdifferent temperatures, an aerosol with the appropriate temperature is required With the heatable aerosol temperature is required. With the heatable aerosol generators of the PLG series, the particle size distribution and the mass flow can be reproducibly adjusted at different temperatures.

Fig. 3:

Particle size distribution of 10W40 motor oil at 40 °C,80 °C and of 15W40 at 80 °C

• Blue = 15W40 at 80 °C

• Green = 10W40 at 80 °C

• Red = 10W40 at 40 °C

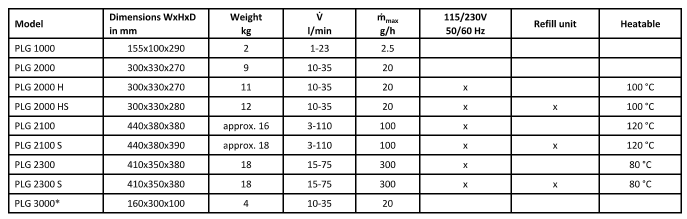

With the PLG 2100 and PLG 2300 devices, high mass flows of up to 100g/h or 300g/h respectively can be generated.

The PLG 2000 HS and PLG 2100 S devices enable nonstop aerosol generation over several days using the automatic refilling unit.

The technical specifications in this sheet are for information only.Technical modifications reserved. V0030314

Table 1: specifications of the Palas aerosol generator PLG 2000 H*= pressure‐resistant; V= volume flow; ṁ = mass flow